Engraving paper material is a great way to put markings and drawings on paper and cardboard branded products, as well as on the packaging of goods. And laser engraving on rubber is indispensable for creating seals, stamps and imprints.

This option of applying images to cardboard or paper, such as laser engraving, is one of the best for the transfer of any individual information, drawings, inscriptions, various labels and other images on these types of materials.

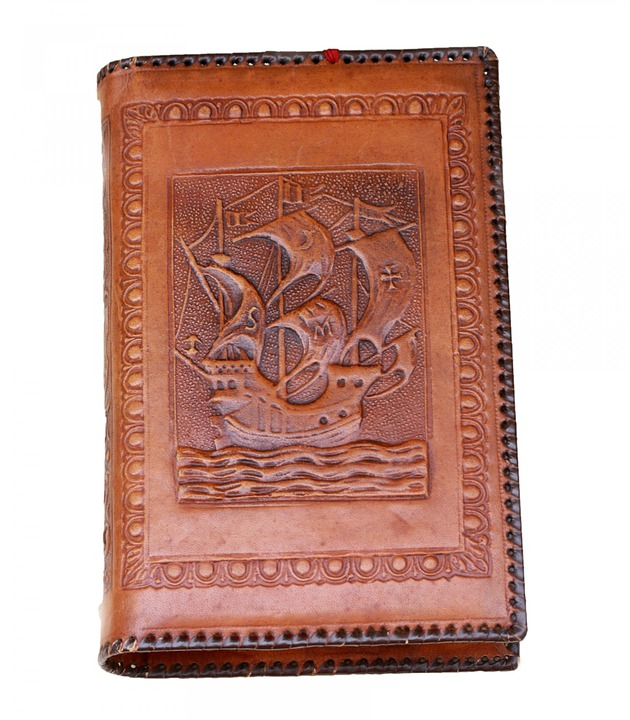

As a result, the popularity of such services as laser engraving on cardboard, is constantly increasing. This is sufficiently contributed to the fact that burned in this way the image and text are very effective, and somewhere even brutal look. During the laser engraving cardboard or paper, the upper layer of material is literally vaporized, forming as a result of deepening, through which the image gets relief, clearly visible to the touch.

Especially spectacular look products, manufactured by multi-layer laser engraving, which provides for the use of several layers of material. The uppermost layer can be engraved through and then overlaid on the next layer of cardboard (more layers can be used), resulting in a sort of layered cake of cardboard or paper.

Importantly, the laser engraving on cardboard makes it possible to create not only a variety of individual products, but also to handle mass orders in the manufacture of promotional products and packaging. In addition, the use of this method is not associated with the production of any clichés or stamps, as required, other more traditional methods of applying images. And this, in turn, makes it possible to produce the smallest runs, up to single batches, without increasing the cost per copy.

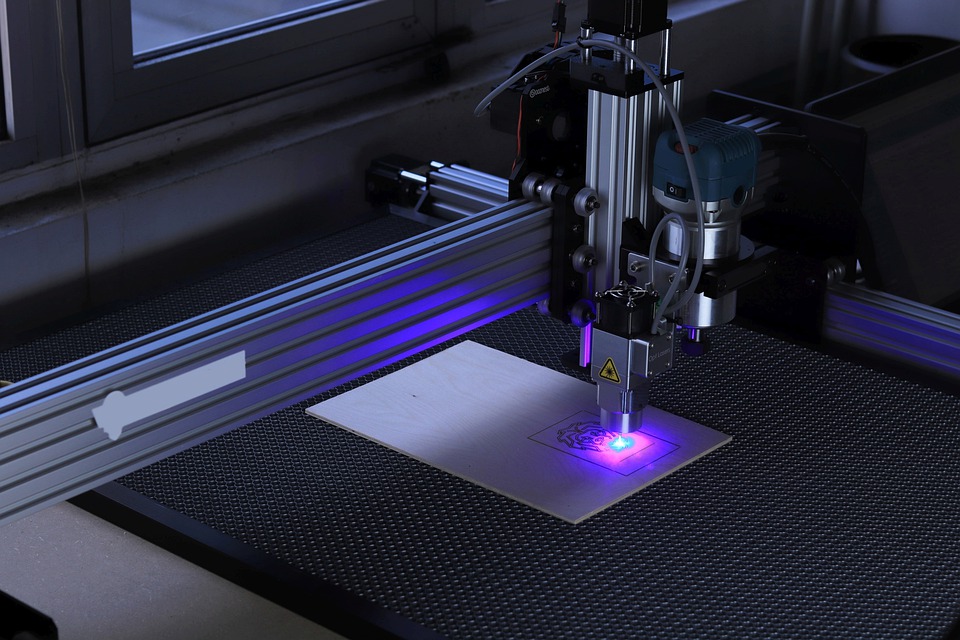

LASER ENGRAVING TECHNOLOGY PAPER AND CARDBOARD

Engraving is done non-contact, without the use of any chemical reagents or dyes. The image is caused by the thermal effect of the laser beam on the material.

Technical specifications of lasers used to engrave paper/cardboard and rubber are the same, but when working with rubber specialists also recommend the use of special filters for combustion products.

Paper and cardboard for laser engraving should be chosen with a denser structure, while among rubber materials a gray synthetic rubber which, unlike the black butadiene styrene rubber (which is strongly not recommended for laser engraving), does not lose its shape, and also does not interact with the stamp paints has proven to be the best.

ADVANTAGES OF LASER CUTTING PAPER (CARDBOARD)

- laser cutting is performed with greater precision;

- laser cutting produces the least amount of waste;

- laser cutting contributes to quality of the cut surface;

- After laser cutting there is no need for additional processing;

- laser cutting has no mechanical effect on the material, i.e. there is no impact on the material in the form of damage, etc. – this contributes to the fact that easily deformable materials have become convenient to cut without damage;

- laser cutting does not require large batches for production of this or that package;

- absolutely any contour can be defined by laser cutting;

- it is possible to produce difficult stencils with less time and material.

USE OF FINISHED PRODUCT

As you can see, almost all products made from different materials, but using the same method of decoration: laser engraving, successfully used in the manufacture of souvenirs.

Laser engraving on paper and cardboard is no exception. High precision laser, capable of imposing on the surface of the material image of any clarity, complexity and fineness, allows you to create a graved paper or cardboard as primitive packing list with the logo of the company-producer, and truly true masterpieces.

In the production of stamps and seals, laser engraving rubber – a truly technological innovation that allows many times to optimize and improve many processes.